If you own an f-body 1st or 2nd generation car from 1967-1981 (F Body chassis by GM found in Pontiac Firebird, Trans Am and Chevrolet Camaro first and second gen vehicles from 67-81) and are getting ready to replace your body to sub-frame bushings, you have three options: stock rubber, polyurethane and solid. If you plan on adding or currently have sub frame connectors connecting your front and rear sub-frames together, then you will most likely be required to use solid body bushings (check your sub-frame connector documentation).

If you own an f-body 1st or 2nd generation car from 1967-1981 (F Body chassis by GM found in Pontiac Firebird, Trans Am and Chevrolet Camaro first and second gen vehicles from 67-81) and are getting ready to replace your body to sub-frame bushings, you have three options: stock rubber, polyurethane and solid. If you plan on adding or currently have sub frame connectors connecting your front and rear sub-frames together, then you will most likely be required to use solid body bushings (check your sub-frame connector documentation).

Rubber Body Bushings – This is the most expensive option and was how the car original came from the factory. This is your option if you are doing a concourse restoration and/or want to keep your vehicle stock. These bushings will deteriorate over time and will need to be replaced after a period of years.

Polyurethane Body Bushings – This is the most popular alternative to rubber body bushings. They are much harder and will last longer than rubber. Polyurethane body bushings will not squeak as they age like some polyurethane A-arm bushings for suspension components sometimes do, so noise for this application is not a factor. Polyurethane may transfer more vibrations from the sub-frame to the body.

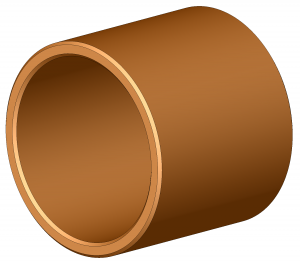

Solid Body Bushings – This is a more permanent solution using bushings typically made out of aluminum. They are solid and should last forever. Solid body bushings will transfer vibrations from the sub-frame to the body. They are required by most sub-frame connectors so body movement does not add stress to sub-frame connections.

We decided to use solid body bushings for Project Trans Am since we plan on installing sub-frame connectors in the future.

Fact: Did you know the 3rd generation F-body chassis did not use body bushings? Instead, the front frame was welded directly to the body.

Installation is straight forward and is typically performed during restoration, when adding sub-frame connectors, or when addressing body flex issues with the front suspension. Most kits come with instructions, new fasteners and torque values. For rusty vehicles, 1-2 weeks of spraying the body bushing fasteners daily with penetrating oil is recommended. Use a breaker bar (do not use am impact wrench) with a 6 point socket to remove these bolts to prevent excessive torquing and damage to the bolt heads.